Fiber-Optic Cable – Fire Ratings

Safety Regulations & Vital Information

Fiber Optic Cable has multiple variations because there are so many characteristics in the cables that can be changed to meet the needs of a specific application. From armored to aerial, each type of fiber-optic cable is manufactured to function in particular areas and under projected environmental conditions. When employing a standard Fiber Cable type, such as indoor distribution fiber cable, an installer must consider the placement in order to meet the specific requirements.

When Fiber Cable is ran throughout a building it will often go through either Riser or Plenum areas, each of which has specific requirements as to what type of cables can be used. In case of a fire, damaged fiber jacket material could release toxic fumes and high amounts of smoke. Because of this, using products with the correct fire ratings is crucial upon installation in order to abide by safety stipulations put into place for the safety of all those occupying the building.

Outlining and understanding the proper protocol when it comes to fire ratings, which are specified to maintain the effectiveness and safety of fiber-optic cable, will ensure a well rounded fiber-optic network.

How to Determine Fire Rating

The jacketing material of a Fiber Optic Cable functions as a protective layer. The level of protection is determined through the specific material used on the cable. There are four types of jacket material available: Polyethylene (PE), Polyvinyl Chloride (PVC), Polyvinyl Difluoride (PVDF), and Low Smoke Zero Halogen (LS).

PE is ideal for outdoor applications because PE jacket material is resistant to abrasions as well as harsh weather, temperature, and moisture conditions.

PVC can be used for both indoor and outdoor applications because PVC jacket material is resistant to more minimal abrasions along with heat and flames.

PVDF is suitable for indoor applications because PVDF jacket material generates little smoke.

LSZH is the best option for indoor applications because LSZH jacket material is devoid of all highly toxic properties that could contaminate the air if the cable were to catch fire.

Certifications of Fire Cable

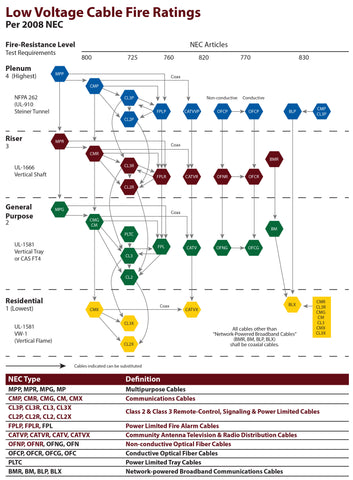

The National Electrical Code (NEC) has established eight levels of fire resistance: OFNP, OFCP, OFNR, OFCR, OFNG, OFCG, OFN, and OFC. The levels of fire resistance are prevalent to the three main installation categories of plenum, riser, and general-purpose.

Optical Fiber Non-conductive Plenum cable (OFNP) and Optical Fiber Conductive Plenum cable (OFCP) are to be applied in plenum spaces where air flows and/or is distributed throughout a building.

Optical Fiber Nonconductive Rise cable (OFNR) and Optical Fiber Conductive Rise cable (OFCR) correspond with riser areas which are vertical shafts or ducts that expand over multiple floors.

Optical Fiber Nonconductive General-Purpose cable (OFNG), Optical Fiber Conductive General-Purpose cable (OFCG), Optical Fiber Nonconductive cable (OFN), and Optical Fiber Conductive cable (OFC) are associated with general purpose areas. The encompassing areas that are not considered to be plenum or riser are regarded as general purpose areas.

|| Through the explicit labels and codes, the most important aspect to recognize is that plenum and riser rated cables are going to be the ideal option when it comes to full building applications.

In summary

Fiber Savvy offers an array of products up to NEC code in order to ensure the optimization and longevity of network applications. Being aware of codes and innovative materials that make up Fiber Cable is the basis of an efficient system built to last and to remain sound under duress.